Automated Sheet Metal Panel Bending

Transform Your Products with Siba Industry's Advanced Panel Bending

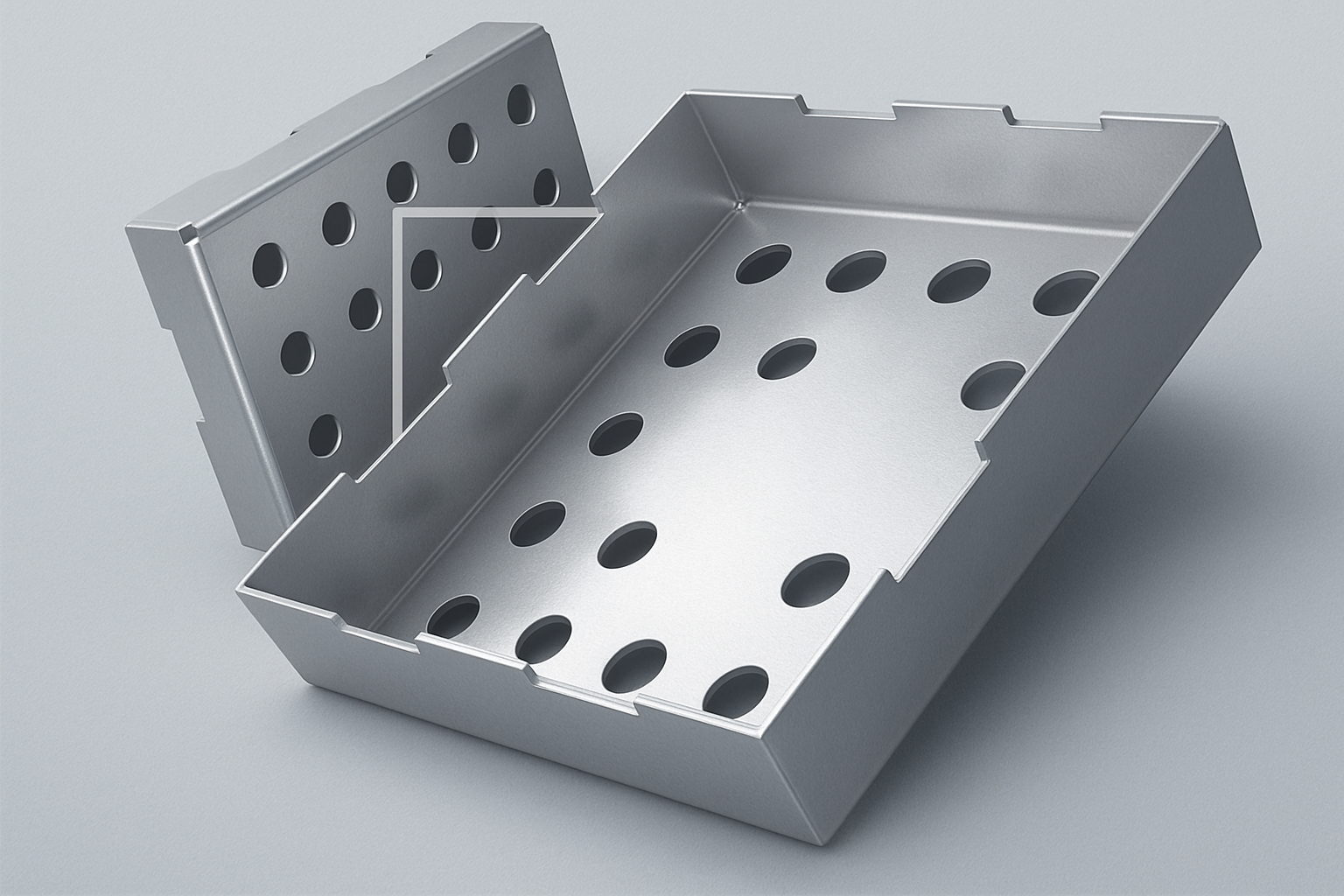

At Siba Industry, we bring a new level of precision and efficiency to sheet metal bending and forming for OEMs across the United States, Euro & Asia. Our fully automated Salvagnini panel benders represent the cutting edge of metal fabrication technology delivering unmatched accuracy, repeatability, and productivity.

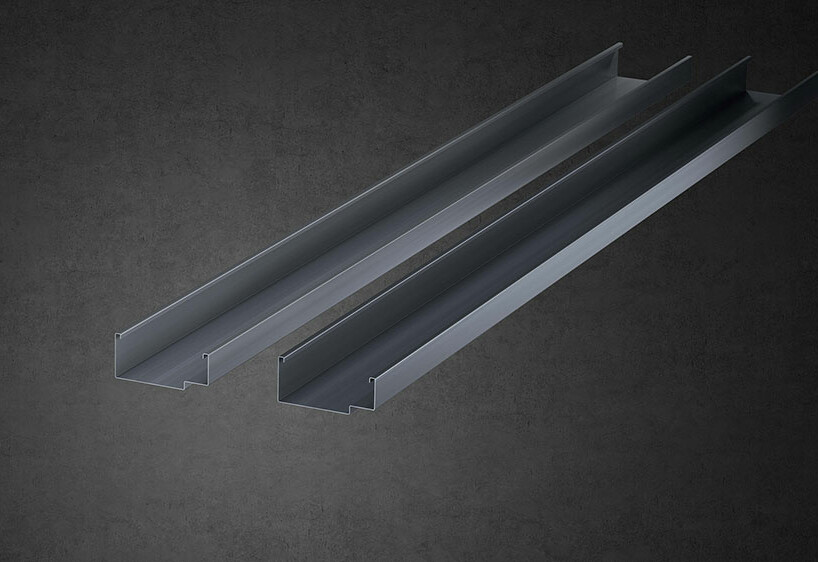

But we offer more than just advanced machinery. Through our collaborative design for manufacturing approach, we help turn your concepts into production ready components with optimized performance and reduced lead times. Whether you’re developing complex enclosures or precision formed panels, Siba Industry is your partner in high performance, cost effective manufacturing solutions.

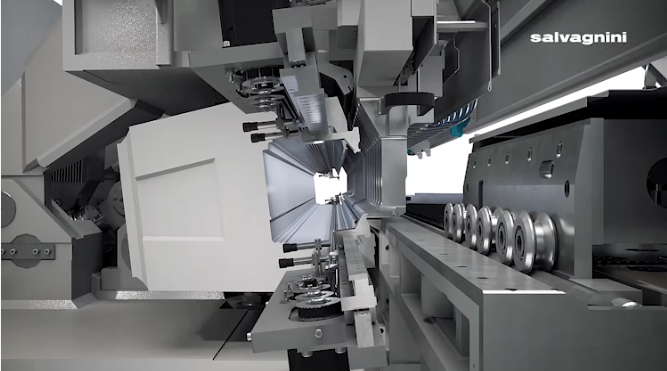

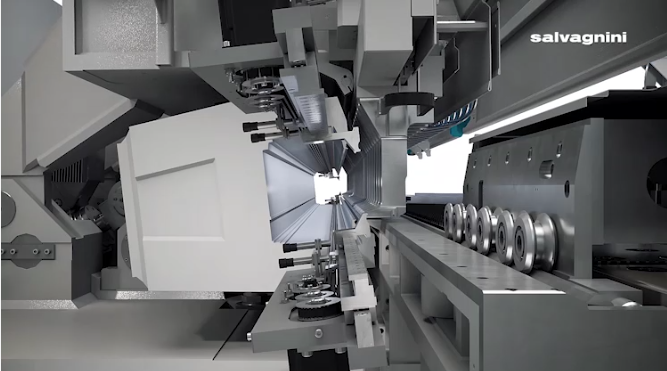

Operating mode: simple, quick and lean

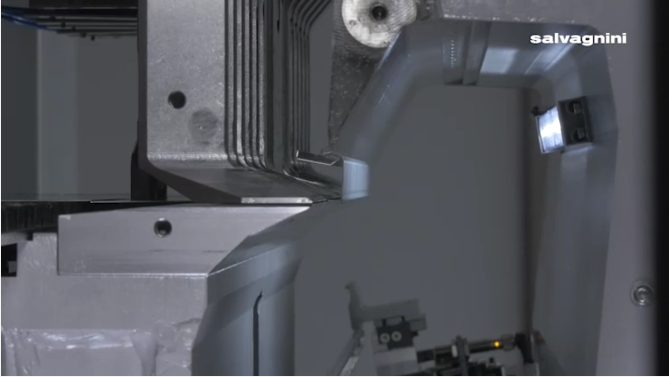

Bending on each side of the sheet is achieved thanks to the controlled interpolated movements of the blades.

Flexible automation

Upper and lower blade, counterblade and blankholder are the four universal tools used to process the whole range of thicknesses and machinable materials, from 0.4 to 3.2 mm, during the cycle and without machine down times or manual re-tooling.

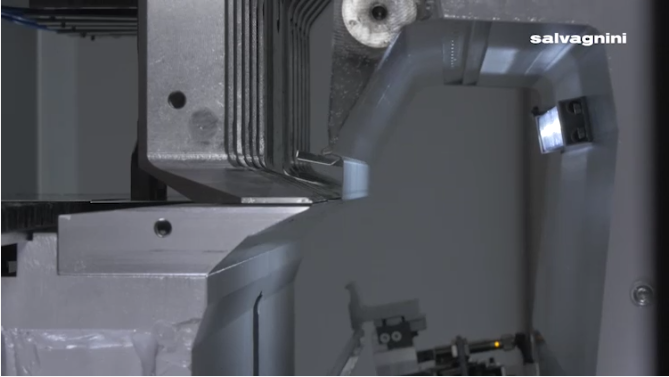

Proprietary bending formula

Developed over the years, the bending formula defines the force and manages the movements of the universal tools, analyzing different parameters in real time, including deflections, temperature and thickness, guaranteeing the precision, repeatability and quality of the finished product.

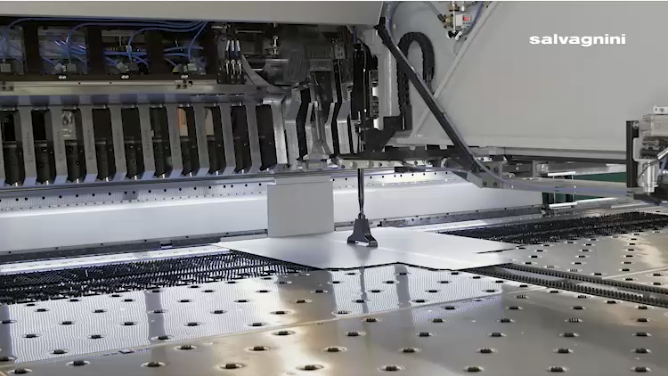

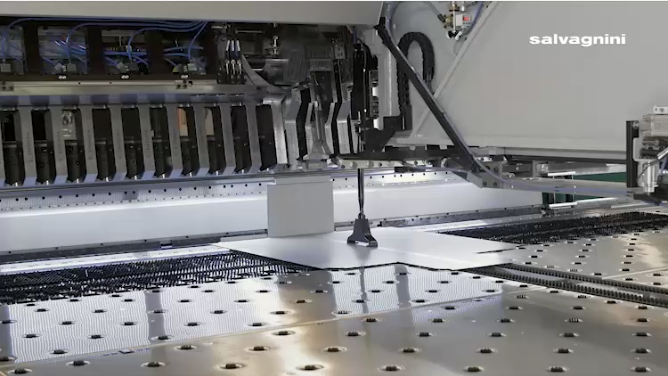

Automatic manipulator: fast and accurate

Quickly and fully automatically, this moves, handles, grips and rotates the sheet metal throughout the whole machining cycle. It requires no manual interventions during the cycle. The operator positions the sheet metal on the worktable and collects the product after bending, performing only the loading and unloading operations.

MAC3.0

MAC3.0 detects any differences in the mechanical characteristics of the material compared to their nominal value during the cycle, adapting the movements of the bending unit and the manipulator to compensate them.

FACE

Intelligent design, intuitive and easy-to-use: FACE is the Salvagnini human-machine interface for the whole product range.

Capabilities

| Model | P4-3220 |

| ||

| Maximum length of incoming sheet (mm) | 3850 |

| ||

| Maximum width of incoming sheet (mm) | 1524 |

| ||

| Maximum diagonal that can be rotated (mm) | 4000 |

| ||

| Maximum bending force (kN) | 660 |

| ||

| Maximum clamping force (kN) | 1060 | |||

| Maximum bending length (mm) | 3200 |

| ||

| Maximum bending height (mm) | 203 |

| ||

| Minimum thickness (mm) | 0.5 |

| ||