At Siba Industry, we recognize that the success of our OEM customers’ products depends on the precision and reliability of every component we produce. That’s why our team works closely with your design and engineering teams reviewing design specifications, offering practical enhancements, and identifying opportunities to improve quality, optimize performance, and reduce both costs and lead times.

Our engineers and manufacturing experts bring a deep commitment to excellence, offering industry leading design support, process optimization insights, and consistently high precision metal components. Backed by responsive, world class customer service, Siba Industry delivers not just products but trusted partnerships.

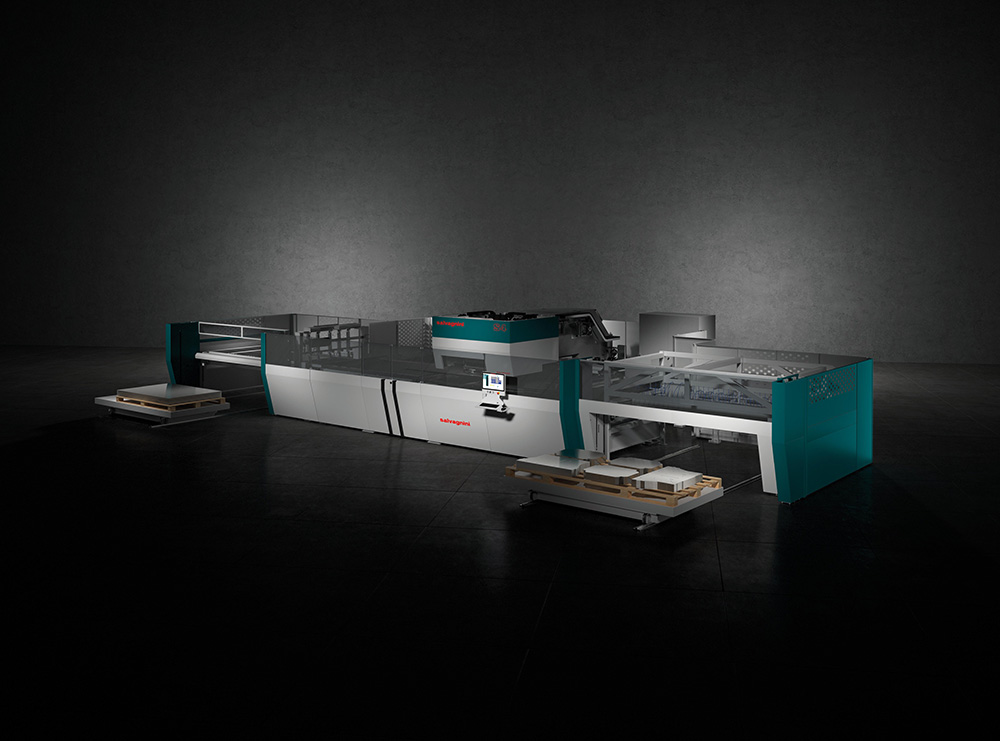

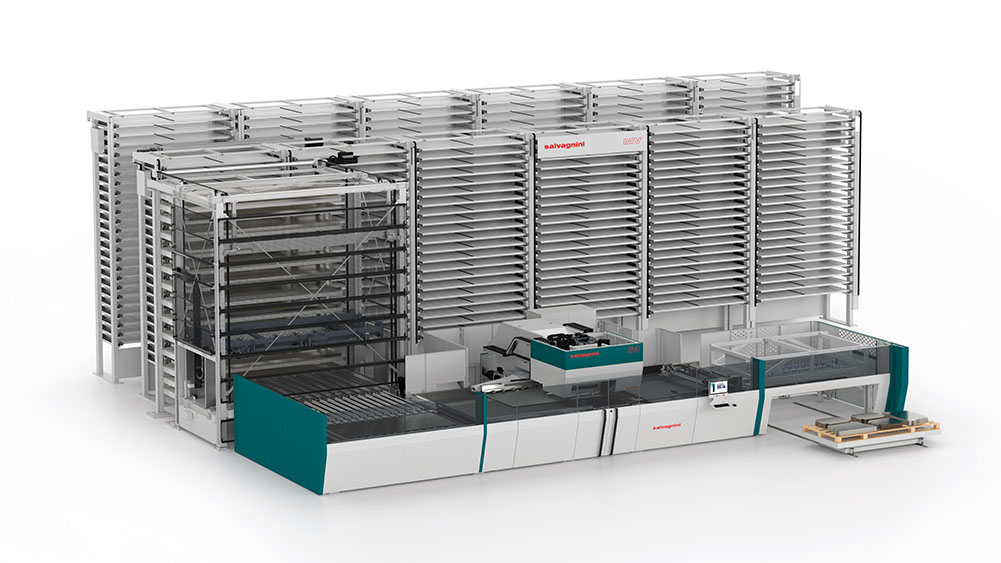

Siba Industry’s advanced automated sheet metal punching technology delivers significant cost-efficiency across all production phases—from prototyping to high-volume manufacturing. By optimizing material usage and streamlining processing time, we help reduce overall production costs while maintaining or exceeding performance standards.

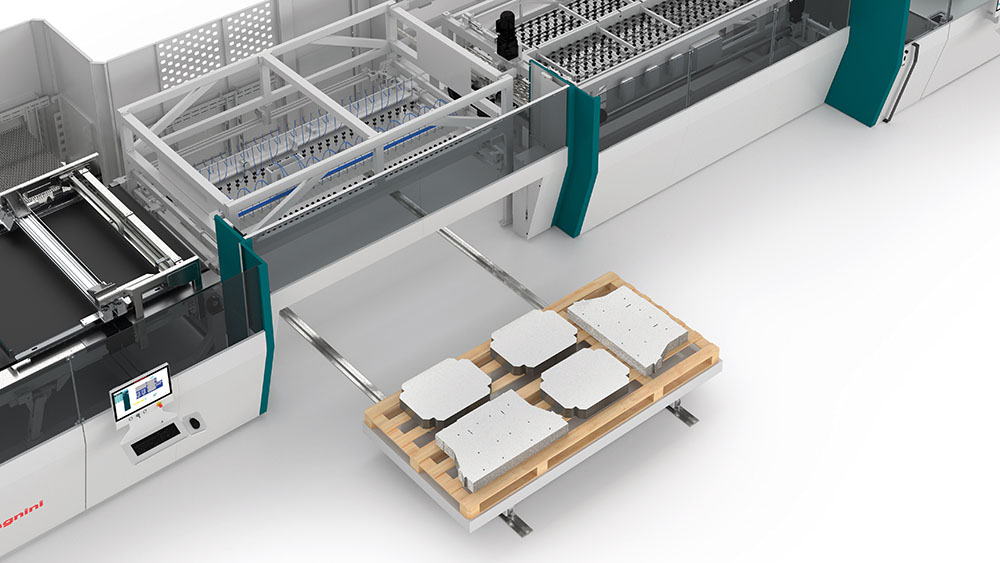

Our engineering team collaborates with OEM clients to design parts with integrated self-fixturing features such as interlocking joints, notches, slot-and-tab locating, hinges, and custom cutouts. These intelligent design strategies eliminate unnecessary fasteners, simplify assemblies, and reduce bill of materials (BOM) complexity.

As a result, projects produced at Siba Industry have realized:

- Over 20% reduction in total manufacturing costs

- 20–60% shorter production cycle times

- 4–17% decrease in material usage

- Fewer BOM line items through smart design integration

- With Siba, efficiency isn’t just a goal — it’s built into every component.

Driven by Innovation. Focused on Your Success.

At Siba Industry, our mission is to maximize productivity while reducing production costs—ensuring your projects are delivered on time, every time. We embrace the latest in automation and advanced manufacturing technologies to enhance flexibility, precision, and speed across all operations.

By investing in state-of-the-art equipment from leading global manufacturers and continually training our team in modern processes, we ensure quality and efficiency at every stage. Our experienced design and engineering teams thoroughly evaluate each product to determine the most effective manufacturing approach and explore design optimizations that can improve performance and reduce cost.

Ready to streamline your metal manufacturing process?

Contact us today to speak with our engineers and discover how Siba Industry can help bring your vision to life with precision, efficiency, and innovation.

Siba Industry: Precision. Innovation. Partnership.

Siba Industry is a trusted manufacturer of precision metal products, recognized for delivering innovative, efficient, and cost-effective solutions. We collaborate closely with OEM clients from initial design support through to final delivery, producing high-quality metal weldments and fabricated components. By seamlessly integrating advanced tools, cutting-edge technology, and skilled expertise, we provide world-class manufacturing services tailored to meet the evolving demands of modern industries.

At Siba Industry, we know that your end‑product’s success hinges on the precision of every single component. That’s why our team partners directly with your design and engineering groups—examining specifications, proposing targeted refinements, and uncovering opportunities to boost performance, shorten lead times, and cut costs.

From concept to completion, our engineers and production specialists deliver industry‑leading design guidance, optimized manufacturing workflows, and exceptionally precise metal parts—all backed by responsive, world‑class support. With Siba Industry, you gain more than a supplier; you gain a dedicated extension of your own engineering team.