Advanced materials, often engineered or synthesized with unique properties, offer significant advantages over traditional materials in various fabrication processes. Here are some of the key benefits:

Improved Performance

- Enhanced strength and durability: Advanced materials can withstand higher loads and harsh environments without compromising performance.

- Increased resistance to corrosion and wear: These materials can resist degradation from exposure to elements and mechanical stress.

- Improved thermal and electrical conductivity: They can efficiently conduct heat or electricity, essential for applications like electronics and energy systems.

- Superior insulation properties: Advanced materials can provide excellent insulation against heat, cold, or sound.

Lighter Weight

- Reduced weight: Advanced materials can be significantly lighter than traditional materials without sacrificing strength.

- Improved fuel efficiency: In transportation applications, lighter weight components lead to better fuel economy.

- Reduced energy consumption: Lighter structures require less energy for transportation and construction.

Cost-Effectiveness

- Long-term savings: While initial costs might be higher, advanced materials often have longer lifespans, reducing maintenance and replacement costs.

- Improved efficiency: Their enhanced properties can lead to more efficient processes and reduced waste.

- Reduced energy consumption: Lighter weight and improved performance can contribute to lower energy consumption.

Sustainability

- Reduced environmental impact: Some advanced materials are derived from sustainable sources or have lower environmental footprints.

- Improved recyclability: Many advanced materials can be recycled or reused more effectively than traditional materials.

- Increased resource efficiency: Their properties can enable more efficient use of materials.

Innovation and Design Flexibility

- New possibilities: Advanced materials can enable innovative designs and applications that were previously impractical.

- Tailored properties: They can be engineered to meet specific requirements, providing greater flexibility in fabrication.

- Enhanced product performance: Advanced materials can improve the functionality and performance of products.

Examples of advanced materials:

- Composite materials: Combining different materials to achieve desired properties (e.g., carbon fiber reinforced plastics).

- Nanomaterials: Materials with structures at the nanoscale, offering unique properties (e.g., graphene).

- Biomaterials: Materials compatible with biological systems, used in medical implants and devices.

- Smart materials: Materials that can sense and respond to changes in their environment (e.g., shape-memory alloys).

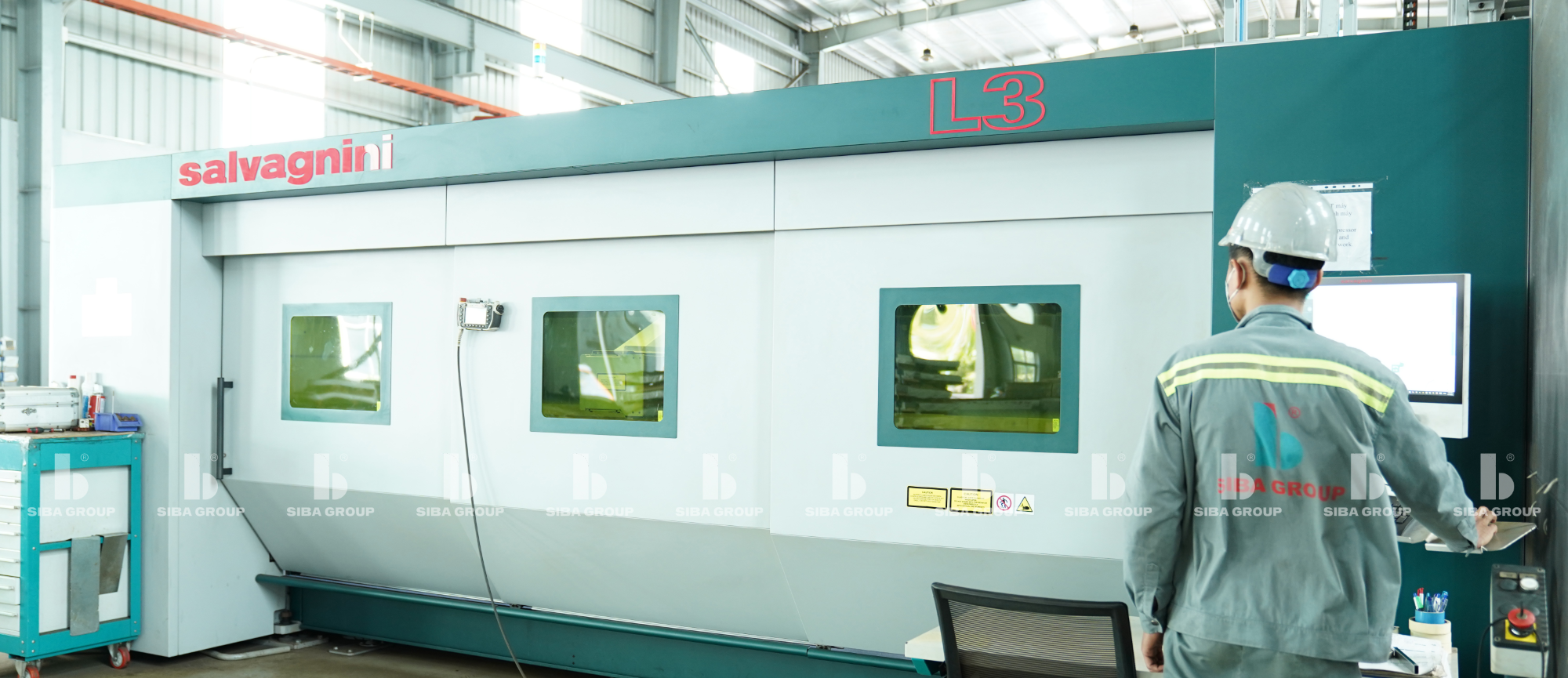

Contact us to learn how Siba Indus can meet your precision metal product manufacturing requirements:

1900 999938

1900 999938

info@siba.com.vn

info@siba.com.vn

![]() 1900 999938

1900 999938![]() info@siba.com.vn

info@siba.com.vn