The sheet metal fabrication process: An overview

Sheet metal fabrication is the process of transforming flat metal sheets into parts and structures of various shapes and sizes. It's a common manufacturing technique used in industries ranging from automotive to aerospace to construction.

Key Steps in the Fabrication Process:

-

Material Selection: The first step involves choosing the appropriate metal for the application. Common materials include:

- Steel: (carbon steel, stainless steel)

- Aluminum: (lightweight and corrosion-resistant)

- Copper: (good conductor of heat and electricity)

- Brass: (a copper-zinc alloy)

-

Cutting: The metal sheet is cut to the desired size and shape. This can be done using:

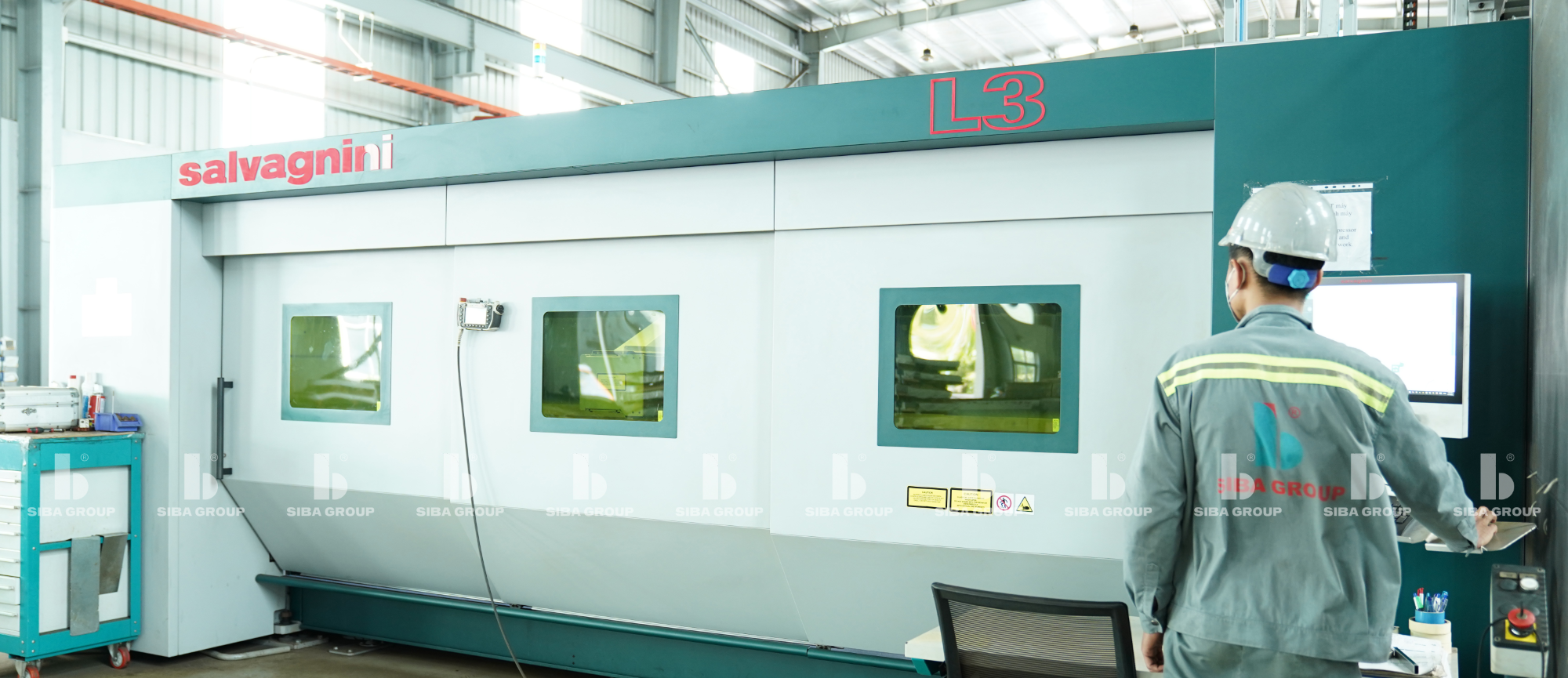

- Laser cutting: Precise cutting with a focused laser beam.

- Waterjet cutting: High-pressure water jet with abrasive particles.

- Plasma cutting: Electrically charged gas stream.

- Shearing: Cutting with a guillotine-like machine.

-

Forming: The cut metal is shaped into the desired three-dimensional form. Common forming techniques include:

- Bending: Creating angles or curves.

- Stamping: Pressing metal into a die to create a specific shape.

- Deep drawing: Forming a hollow shape from a flat sheet.

- Flanging: Creating a raised edge around a sheet.

-

Joining: Components are joined together using various methods:

- Welding: Fusing metal pieces together with heat and pressure.

- Riveting: Fastening pieces together with metal pins.

- Bolting: Connecting pieces with bolts and nuts.

- Adhesives: Bonding pieces together with a glue-like substance.

-

Finishing: The final product is often treated to improve its appearance, durability, or functionality. This may include:

- Painting: Applying a protective or decorative coating.

- Powder coating: A durable, electrostatic powder finish.

- Plating: Applying a thin layer of metal for corrosion resistance or aesthetics.

- Anodizing: Creating a protective oxide layer on aluminum.

Applications of sheet metal fabrication:

- Automotive: Car bodies, components, and accessories

- Aerospace: Aircraft parts, structural components

- Construction: Building materials, cladding, HVAC systems

- Consumer goods: Appliances, electronics, furniture

- Industrial machinery: Components, housings, enclosures

Contact us to learn how Siba Indus can meet your precision metal product manufacturing requirements:

1900 999938

1900 999938

info@siba.com.vn

info@siba.com.vn

![]() 1900 999938

1900 999938![]() info@siba.com.vn

info@siba.com.vn