Introduction to Sheet Metal Fabrication

Sheet metal fabrication is the process of cutting, bending, and shaping sheet metal into various components or products. It's a fundamental technique used in many industries, including automotive, aerospace, construction, and consumer goods.

Basic Processes Involved in Sheet Metal Fabrication

-

Cutting: This involves separating sheet metal into desired shapes. Common cutting methods include:

- Shearing: Using a machine with two blades to cut the metal.

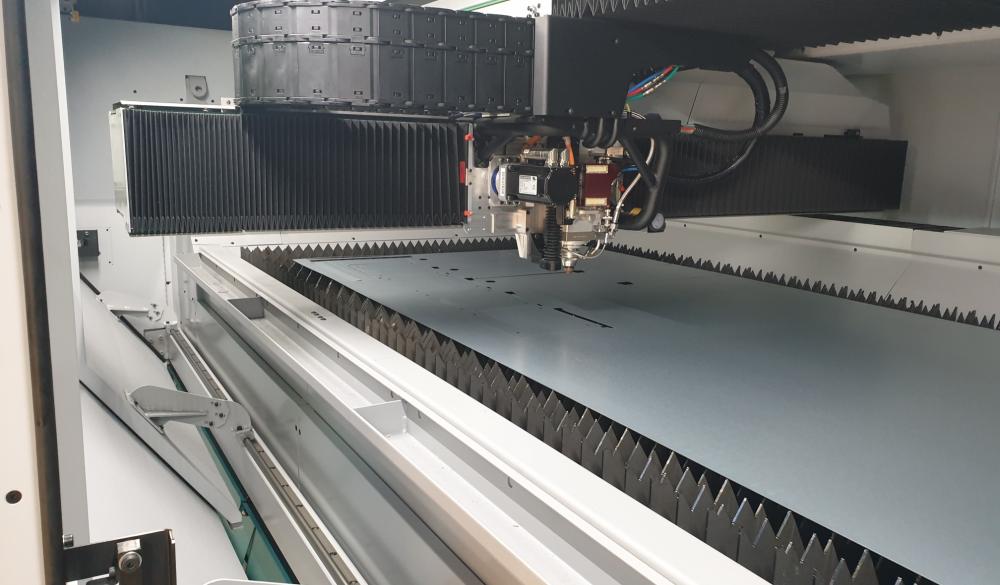

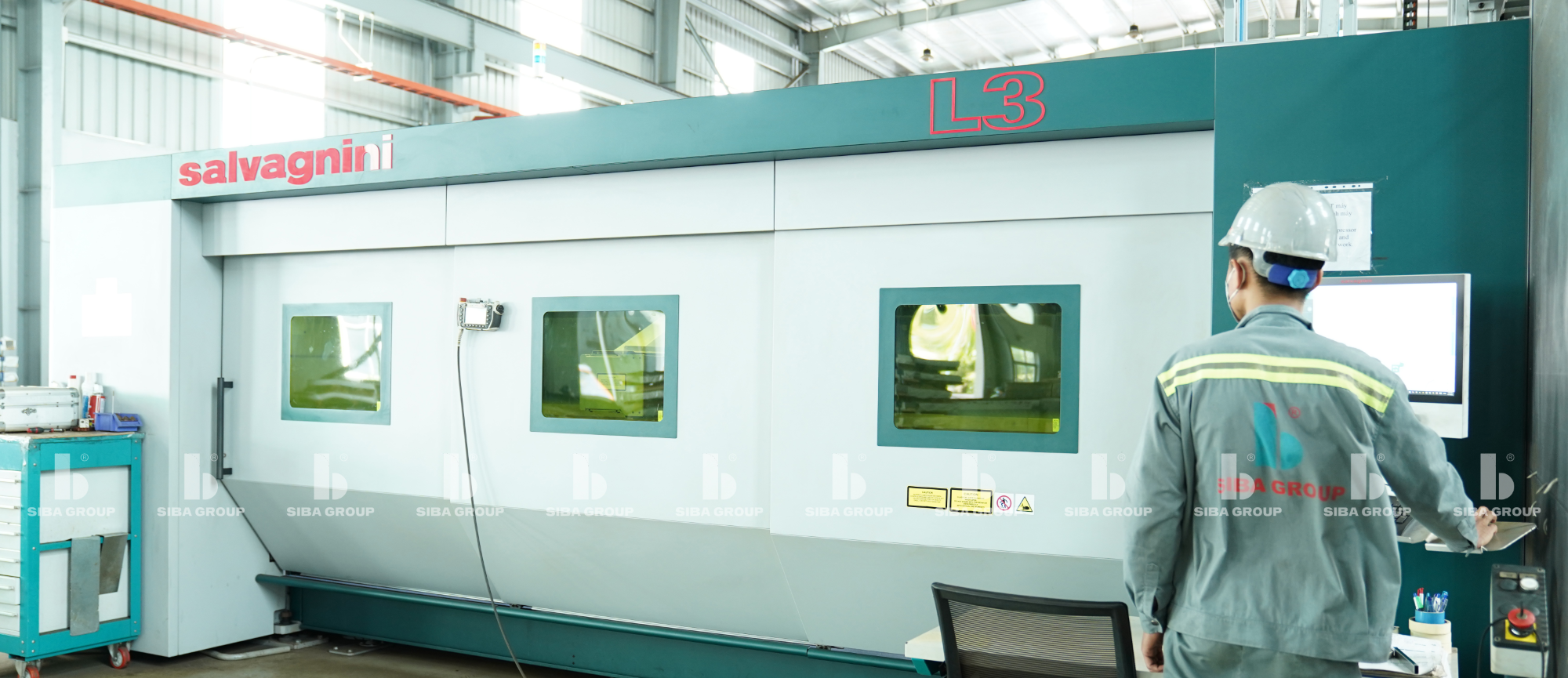

- Laser cutting: Using a focused laser beam to cut through the material.

- Waterjet cutting: Using a high-pressure water jet with abrasive particles to cut the metal.

- Punching: Using a die to punch holes or shapes into the metal.

-

Bending: This is the process of forming the metal into desired curves or angles. Common bending methods include:

- Press brake: Using a machine with a hydraulic or mechanical press to bend the metal.

- Roll forming: Using a series of rollers to gradually bend the metal into a desired shape.

- Hand bending: Manually bending the metal using tools like a hammer or vise.

-

Forming: This involves shaping the metal into complex three-dimensional shapes. Common forming methods include:

- Stamping: Using a die to press the metal into a desired shape.

- Drawing: Pulling the metal through a die to form a hollow shape.

- Hydroforming: Using water pressure to form the metal into a desired shape.

-

Finishing: This involves treating the metal to improve its appearance, durability, or functionality. Common finishing methods include:

- Welding: Joining pieces of metal together using heat and pressure.

- Riveting: Fastening pieces of metal together using rivets.

- Painting: Applying a coating to the metal to protect it from corrosion and improve its appearance.

- Powder coating: Applying a powdered coating to the metal and then curing it in an oven.

Materials Used in Sheet Metal Fabrication

Common materials used in sheet metal fabrication include:

- Steel: The most widely used material due to its strength and durability.

- Aluminum: Lightweight and corrosion-resistant, making it suitable for applications where weight is a concern.

- Stainless steel: Highly resistant to corrosion and staining, making it ideal for outdoor applications.

- Copper: Good conductor of heat and electricity, often used in electrical and plumbing applications.

- Brass: A copper-zinc alloy with a golden color and good machinability.

Contact us to learn how Siba Indus can meet your precision metal product manufacturing requirements:

1900 999938

1900 999938

info@siba.com.vn

info@siba.com.vn

![]() 1900 999938

1900 999938![]() info@siba.com.vn

info@siba.com.vn