The Future of Sheet Metal Fabrication: Trends and Innovations

Sheet metal fabrication, a cornerstone of manufacturing industries, is undergoing a significant transformation driven by technological advancements and evolving market demands. Here are some key trends and innovations shaping its future:

1. Advanced Manufacturing Technologies

- Additive Manufacturing (3D Printing): This technology is gaining traction for prototyping and small-scale production of complex sheet metal components.

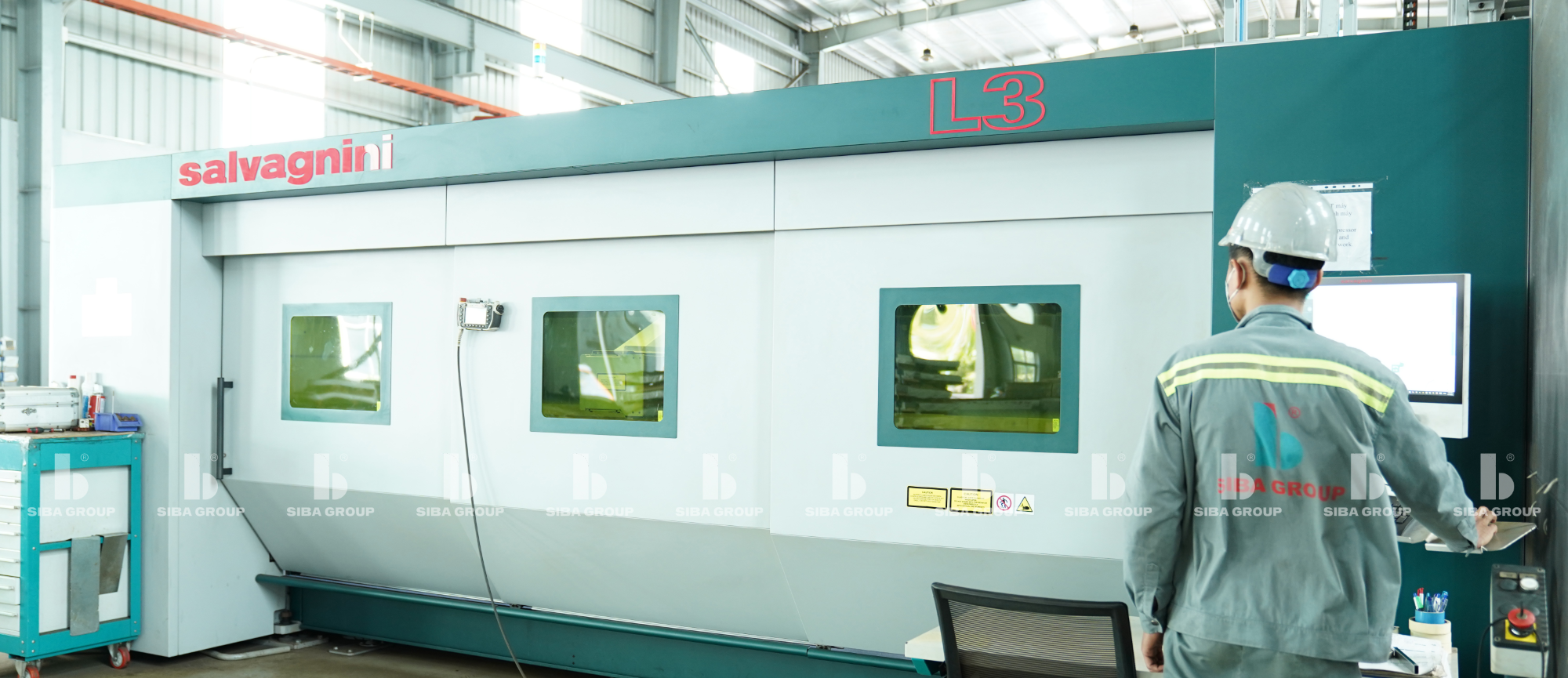

- Laser Cutting: High-power lasers offer precision, speed, and reduced waste, making them a preferred choice for intricate cutting tasks.

- Waterjet Cutting: Ideal for cutting materials with varying thicknesses and hardness, waterjet cutting minimizes heat-affected zones.

- Automation and Robotics: Increasingly automated processes, including robotic welding and bending, improve efficiency and consistency.

2. Smart Manufacturing

- Industry 4.0: The integration of digital technologies into manufacturing processes is enabling real-time data collection, analysis, and optimization.

- IoT and Sensors: Connected devices and sensors monitor equipment health, production efficiency, and quality control.

- Predictive Maintenance: By analyzing data, manufacturers can anticipate equipment failures and schedule maintenance proactively.

3. Lightweight Materials

- Advanced Alloys: Materials like aluminum alloys, magnesium alloys, and high-strength steels are being used to create lighter and stronger components, reducing weight and improving fuel efficiency in industries like automotive and aerospace.

- Composite Materials: Combining metals with other materials, such as plastics or ceramics, can create hybrid components with enhanced properties.

4. Sustainability and Circular Economy

- Recycling and Reuse: Efforts are underway to increase the recyclability of sheet metal and reduce waste.

- Sustainable Materials: Sourcing materials from sustainable sources and minimizing environmental impact is becoming a priority.

5. Customization and Mass Personalization

- Flexible Manufacturing: Technologies like additive manufacturing and laser cutting enable mass customization, allowing manufacturers to produce tailored products in smaller quantities.

- Digital Manufacturing: Digital twins and simulation tools facilitate rapid prototyping and customization.

6. Emerging Applications

- Electric Vehicles: The rise of electric vehicles is driving demand for lightweight, high-strength sheet metal components.

- Renewable Energy: Sheet metal fabrication plays a role in the production of solar panels, wind turbine components, and other renewable energy technologies.

- Medical Devices: Precision sheet metal fabrication is used to create medical devices with intricate geometries and high tolerances.

In conclusion, the future of sheet metal fabrication is marked by innovation, sustainability, and advanced technologies. By embracing these trends, manufacturers can position themselves for growth and success in a rapidly evolving market.

Contact us to learn how Siba Indus can meet your precision metal product manufacturing requirements:

1900 999938

1900 999938

Email: info@siba.com.vn

![]() 1900 999938

1900 999938